Sheet Metal Drawings

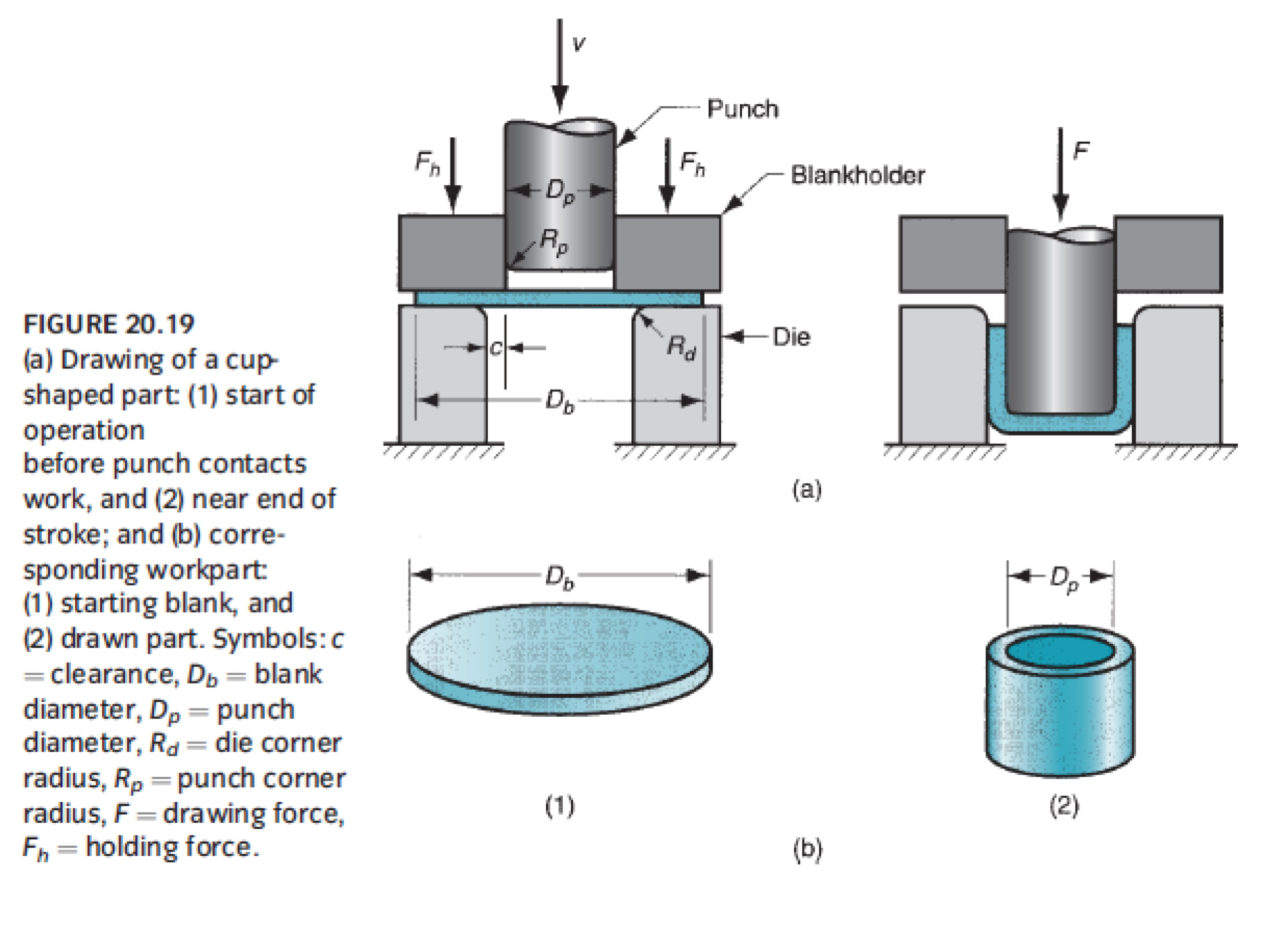

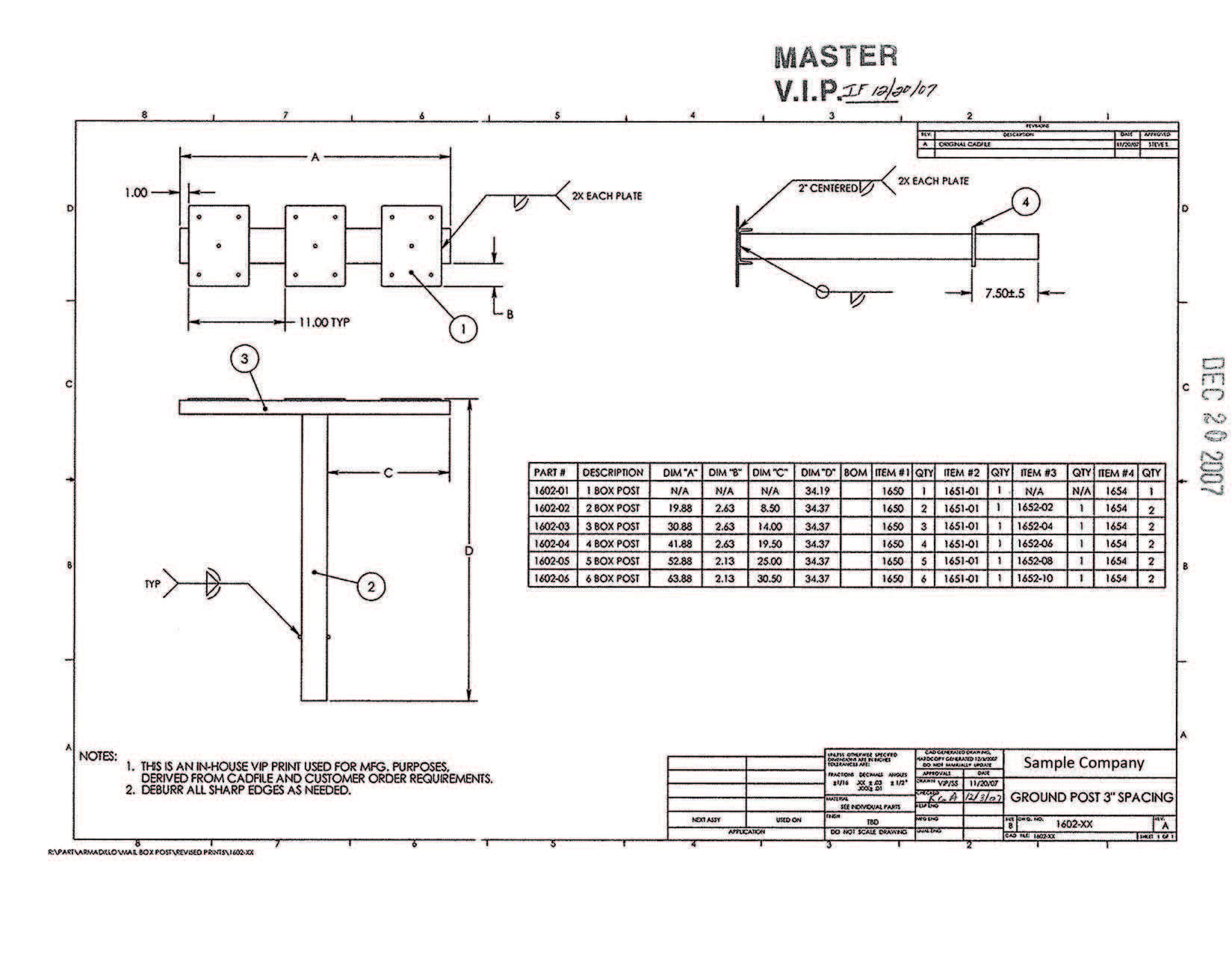

Sheet Metal Drawings - Web sheet metal design software like autodesk fusion 360 includes a combination of 2d and 3d design capabilities. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. 2 sheet metal design for. Web drawings of sheet metal parts. You can also perform the following sheet metal drawing operations: Web what are sheet metal cad drawings? Include grain direction as needed; Use the exact hardware name when possible; List part numbers, not just the part name; It is a cut in a straight line across a strip, sheet or bar. Web a fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc…). This means your sheet can contain views of both the model and its flat pattern. Users can define parameters such as material thickness, bend allowances, hole sizes, and other geometric features relevant to. In this tutorial video we will learn how to sketch sheet metal drawings in solidworks with the help of sheet metal tools. When creating views of flat patterns take note of the options to include the bend extents and punch centers. Web for your drawing preparation, check out this article with our top tips for creating better sheet metal drawings. Web develop sheet metal models with fewer steps. List part numbers, not just the part name; Use the exact hardware name when possible; Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. Web drawings of sheet metal parts. Web when designing sheet metal parts, the order preference for use of feature tools are as follows: For someone who may be taking that first step into having a sheet metal design created, here are the essential things that your drawing needs. This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized. 2 sheet metal design for. Use the convert to sheet metal feature. What are the sheet metal forming processes in canmaking? Use the insert bends feature. Web drawings of sheet metal parts. This tutorial, which is common to the sheet metal design user's guide and to the generative sheet metal design user's guide, is illustrated using screen captures from the sheet metal design workbench. Web among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. Web 1 5 ways. Web drawings of sheet metal parts. These drawings are typically created by engineers or draftspersons and used by sheet metal fabricators to produce accurate and. Web following are the 9 different types of sheet metal operations: Web solidworks tutorial sheet metal drawings. Web a fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Web develop sheet metal models with fewer steps. A title block with your company name, part number, part description, scale, tolerances, units, etc. Web 1 5 ways to optimize drawings for precision sheet metal fabrication services. It is an essential aspect of manufacturing in. Shop drawings should be created by someone in the company familiar with detailing. Sheet metal shop drawings are detailed technical drawings that provide instructions and information for the fabrication and assembly of sheet metal components. Web when designing sheet metal parts, the order preference for use of feature tools are as follows: Web what are sheet metal cad drawings? 55k. Sheet metal parts are known for their durability, which makes them great for end use applications. Web drawings of sheet metal parts. In this tutorial video we will learn how to sketch sheet metal drawings in solidworks with the help of sheet metal tools. When using the insert bends or convert to sheet metal features, apply the features as early. You can create *.dxf files of sheet metal flat patterns without creating a drawing. 2 sheet metal design for. Web develop sheet metal models with fewer steps. List part numbers, not just the part name; Use the insert bends feature. This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Users can define parameters such as material thickness, bend allowances, hole sizes, and other geometric features relevant to sheet metal fabrication. Use the exact hardware name when possible; Web the art of drawing metal sheets has enabled revolutionary advancements in design paradigms and provided pathways for improved functional capabilities. Web among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. It is a best practice to dimension to virtual intersection points and. Web a fully dimensioned drawing including dimensions for formed bends, countersinks, holes, flanges. What are the sheet metal forming processes in canmaking? This allows engineers and designers to create precise models of sheet metal components. Sheet metal parts are known for their durability, which makes them great for end use applications. • show a bend order table.

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

sheet metal drawings for practice pdf sketchuptutorialspart2

Metal Drawings at Explore collection of Metal Drawings

Sheet Metal Shakotis

Sheet Metal Practice Drawing

Sheet Metal Practice Drawing

sheet metal drawings for practice pdf Alyse Britton

Solidworks Tutorial Sheet metal drawings YouTube

Sheet Metal Drawing Pdf EASY DRAWING STEP

Autodesk Inventor Sheet metal Drawing Tutorial Basics YouTube

These Drawings Are Typically Created By Engineers Or Draftspersons And Used By Sheet Metal Fabricators To Produce Accurate And.

Web Following Are The 9 Different Types Of Sheet Metal Operations:

Web When Designing Sheet Metal Parts, The Order Preference For Use Of Feature Tools Are As Follows:

Web Extracting Drawings From The Sheet Metal Part All Together, These Tasks Should Take About 15 Minutes To Complete.

Related Post: