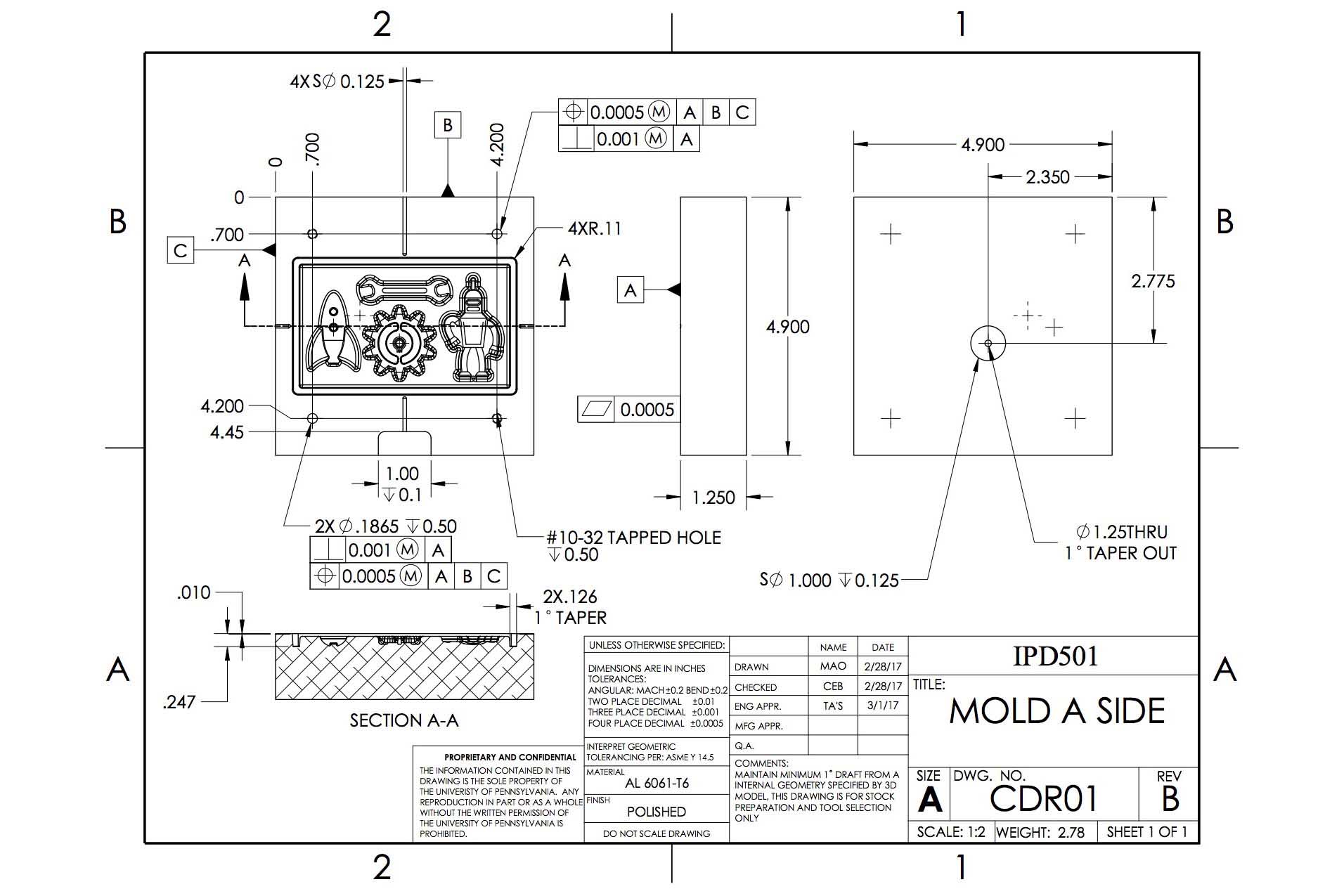

Mold Drawing

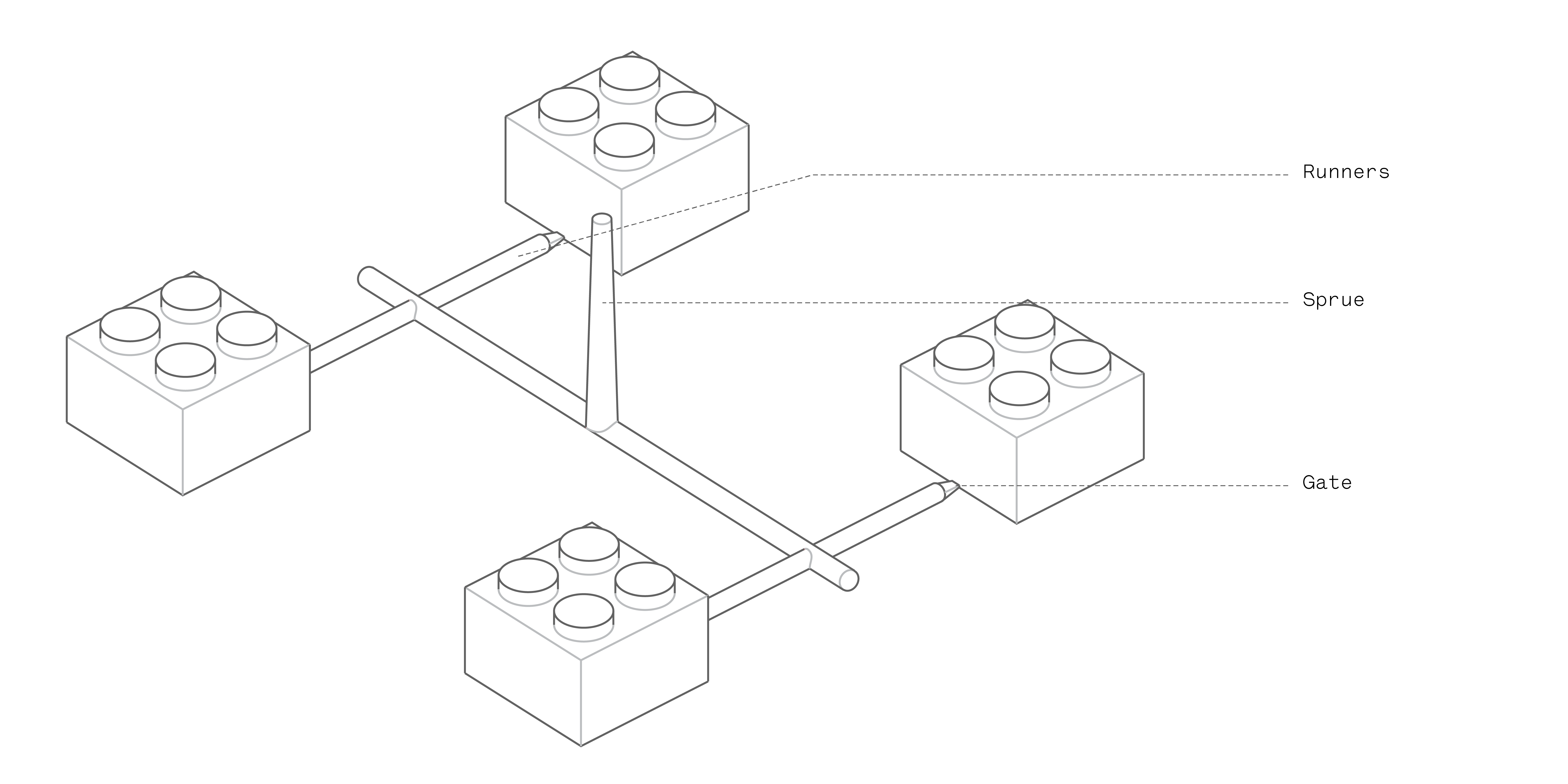

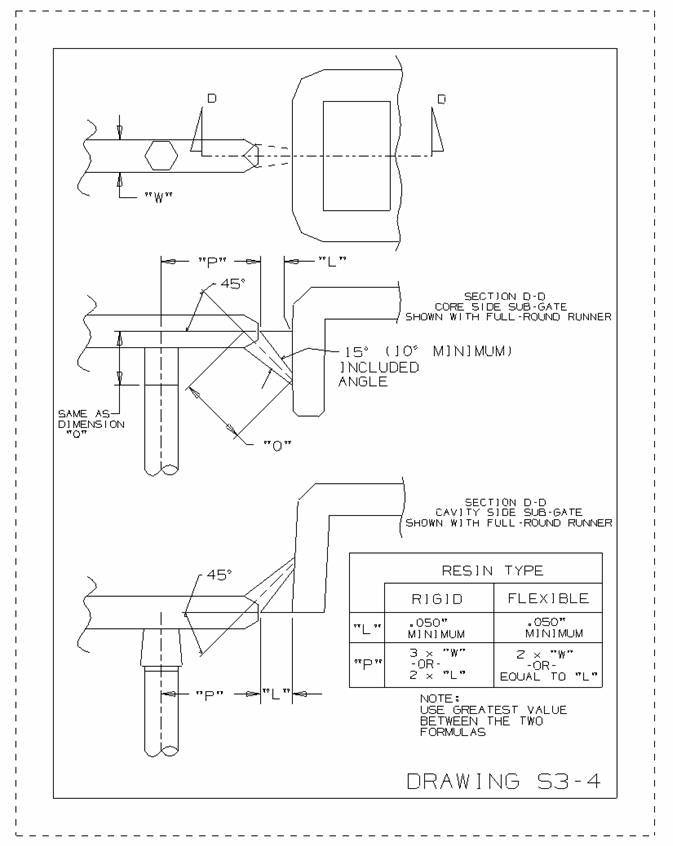

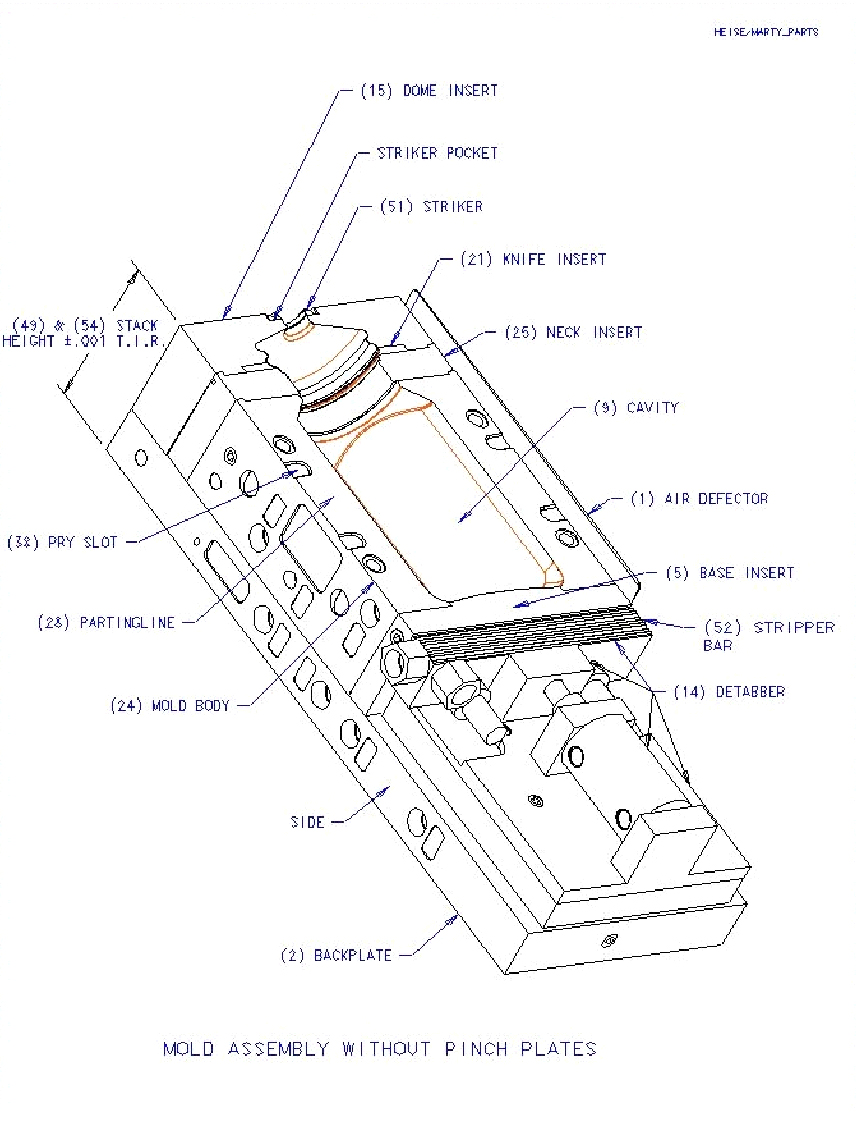

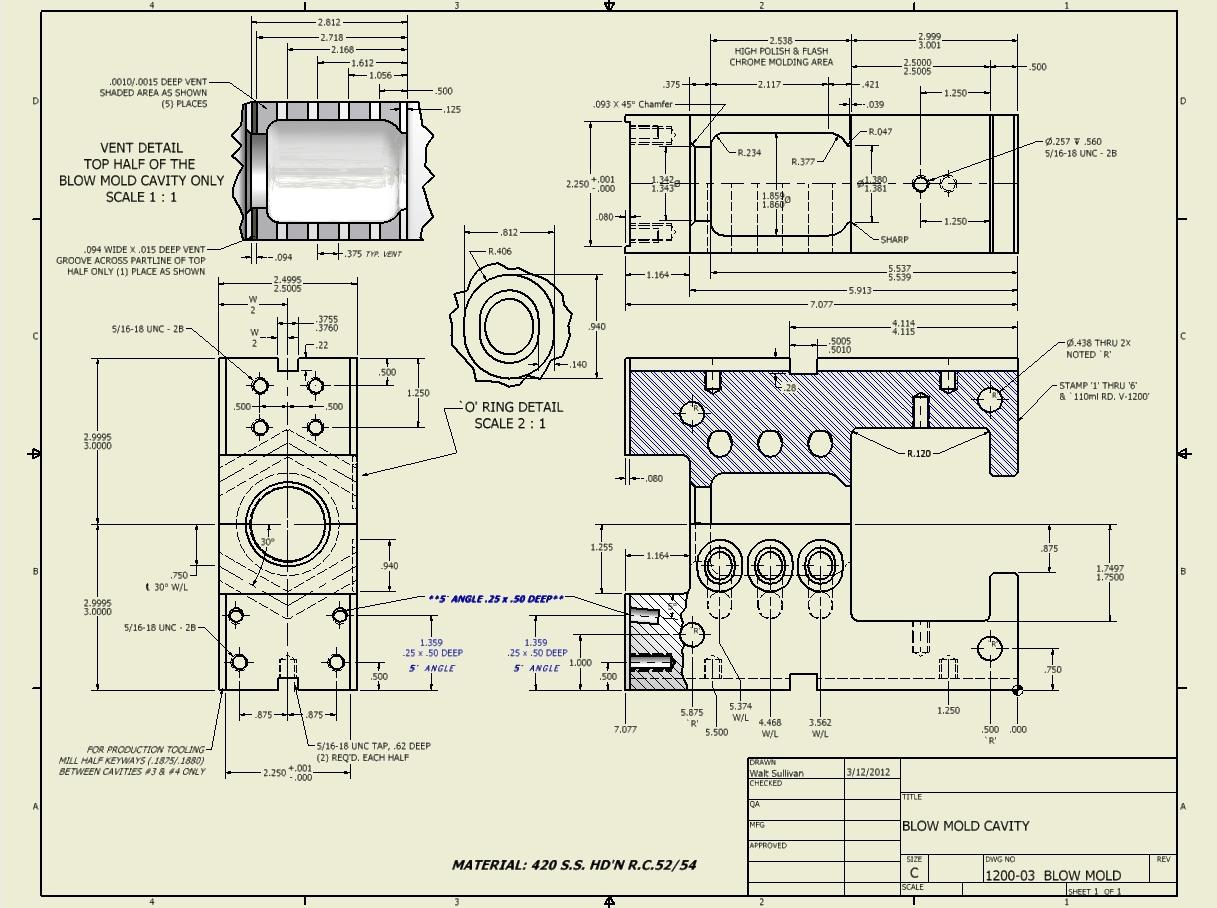

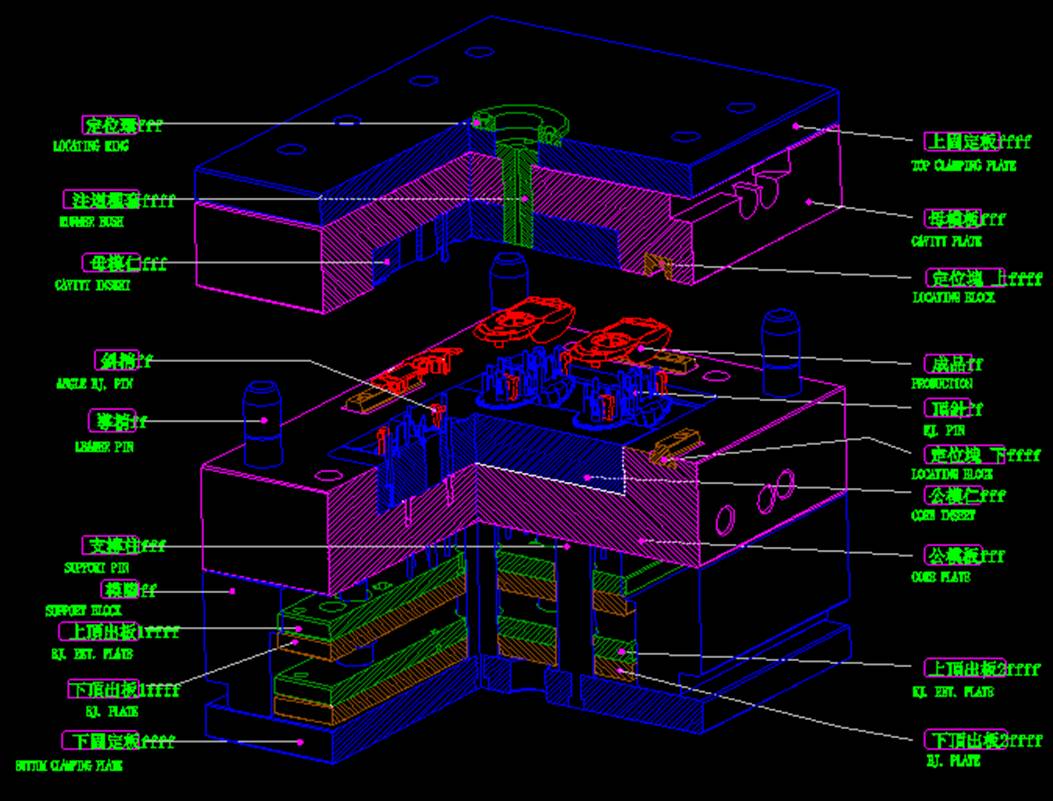

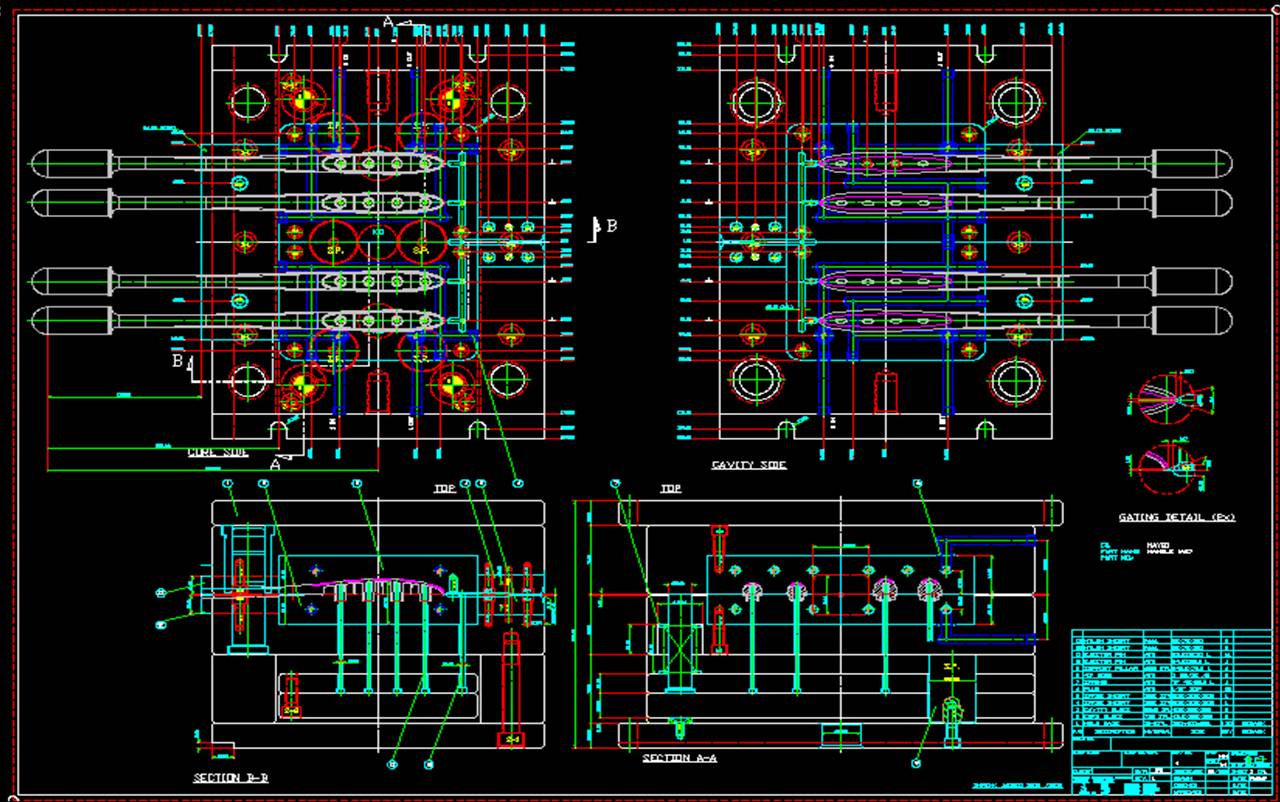

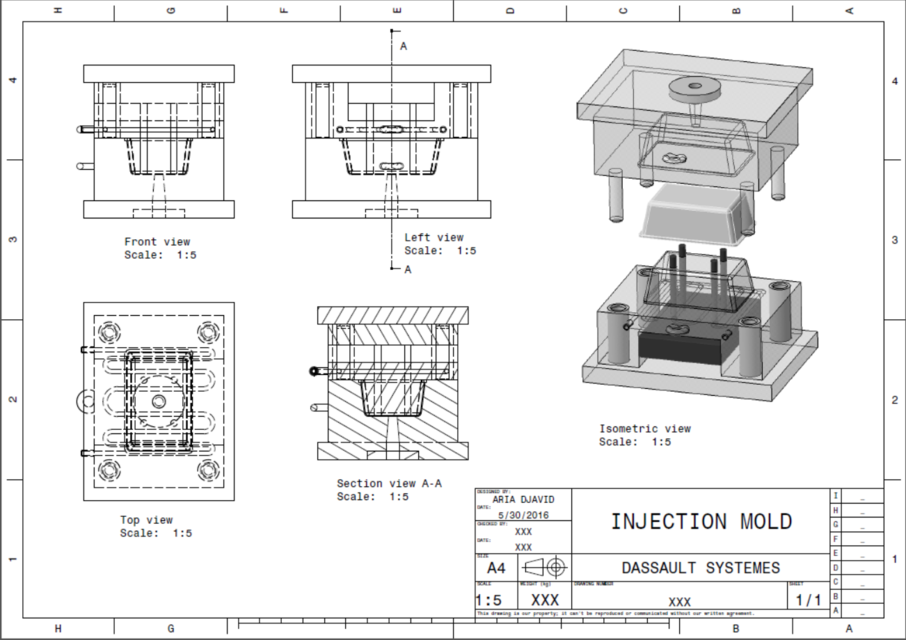

Mold Drawing - Web process drawings are usually on mold assembly drawing. Web introduction before start with a new need to get as much tion on as possible. Web what are the design specifications for injection mold drawings? Web injection molding is a fast and efficient way to produce plastic parts. Web by providing information regarding design, dimensions, and specifications of a mold’s dimensions as well as production processes; Dec 1, 2022 | blog, mold design dips. Web for a comprehensive view of the mold, it’s advisable to request the mold drawing. Find out the factors that affect the. Web this approved part drawing, along with the details of the mold design (typically called the mold design order or order confirmation), can now be used to. Choose a suitable standard mold base based on the mold’s dimensions, and prefer standard mold components whenever. It provides a detailed way or like a sample of visualizing the mold to be built. 1.subject content and scope of application. Web what are the design specifications for injection mold drawings? ️ pigeon is undoubtedly one of the most delicate types of poultry availabl. Web a cad drawing is a digital drawing showing your design in either 2d or. Choose a suitable standard mold base based on the mold’s dimensions, and prefer standard mold components whenever. It provides a detailed way or like a sample of visualizing the mold to be built. Web a cad drawing is a digital drawing showing your design in either 2d or 3d format. This standard specifies the contents and expression. Web what are. Producing a mold is costly and can’t thousands of miles away. Web preparations before mold design. Web injection molding is a fast and efficient way to produce plastic parts. Mold drawings are mainly mold designs based on customer information and. The core and the cavity. The tool that it uses, an injection mold, has two main parts: 1.subject content and scope of application. Web a cad drawing is a digital drawing showing your design in either 2d or 3d format. Web process drawings are usually on mold assembly drawing. Web effects of mold temperature and pressure on shrinkage 0.030 0.000 0.010 0.005 0.015 0.020 0.025. Dec 1, 2022 | blog, mold design dips. This standard specifies the contents and expression. The tool that it uses, an injection mold, has two main parts: Mold drawings are mainly mold designs based on customer information and. Whether you're a beginner or an experienced artist, our guide will help you mast. Web engineers will consider the 11 aspects below when creating mold drawings for the program, to guarantee the trial’s success and the accuracy of the mold. Web preparations before mold design. Web j) standard mold base selection: It provides a detailed way or like a sample of visualizing the mold to be built. Web for a comprehensive view of the. Web j) standard mold base selection: Dec 1, 2022 | blog, mold design dips. It provides a detailed way or like a sample of visualizing the mold to be built. Web for a comprehensive view of the mold, it’s advisable to request the mold drawing. The tool that it uses, an injection mold, has two main parts: Web effects of mold temperature and pressure on shrinkage 0.030 0.000 0.010 0.005 0.015 0.020 0.025 100 120 140 160 180 200 220 240 mold temperature (f) ldpe pp nylon. Web what are the design specifications for injection mold drawings? Dec 1, 2022 | blog, mold design dips. Mold drawings are mainly mold designs based on customer information and. This. Web what are the design specifications for injection mold drawings? This standard specifies the contents and expression. The tool that it uses, an injection mold, has two main parts: Web a cad drawing is a digital drawing showing your design in either 2d or 3d format. Mold drawings are mainly mold designs based on customer information and. The mold drawing is especially valuable for any future repair needs. Dec 1, 2022 | blog, mold design dips. Producing a mold is costly and can’t thousands of miles away. The core and the cavity. Web learn how to design a mold that will be able to withstand the extreme conditions of injection molding, such as high temperatures and pressures. Web preparations before mold design. 1.subject content and scope of application. Web process drawings are usually on mold assembly drawing. This standard specifies the contents and expression. ️ pigeon is undoubtedly one of the most delicate types of poultry availabl. The mold drawing is especially valuable for any future repair needs. Producing a mold is costly and can’t thousands of miles away. I would like to thank: Web learn how to design a mold that will be able to withstand the extreme conditions of injection molding, such as high temperatures and pressures. Web for a comprehensive view of the mold, it’s advisable to request the mold drawing. Whether you're a beginner or an experienced artist, our guide will help you mast. The core and the cavity. Mold drawings are mainly mold designs based on customer information and. Web what are the design specifications for injection mold drawings? Web engineers will consider the 11 aspects below when creating mold drawings for the program, to guarantee the trial’s success and the accuracy of the mold. Find out the factors that affect the.

Mold Drawing at Explore collection of Mold Drawing

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing by Regina Jeffers Fine Art America

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at GetDrawings Free download

Mold Drawing at Explore collection of Mold Drawing

Web This Approved Part Drawing, Along With The Details Of The Mold Design (Typically Called The Mold Design Order Or Order Confirmation), Can Now Be Used To.

Web By Providing Information Regarding Design, Dimensions, And Specifications Of A Mold’s Dimensions As Well As Production Processes;

Draw Assembly Structure Diagram When Drawinn Final Assembly Drawing, Use A 1:

Choose A Suitable Standard Mold Base Based On The Mold’s Dimensions, And Prefer Standard Mold Components Whenever.

Related Post: