Deep Draw Metal Stamping

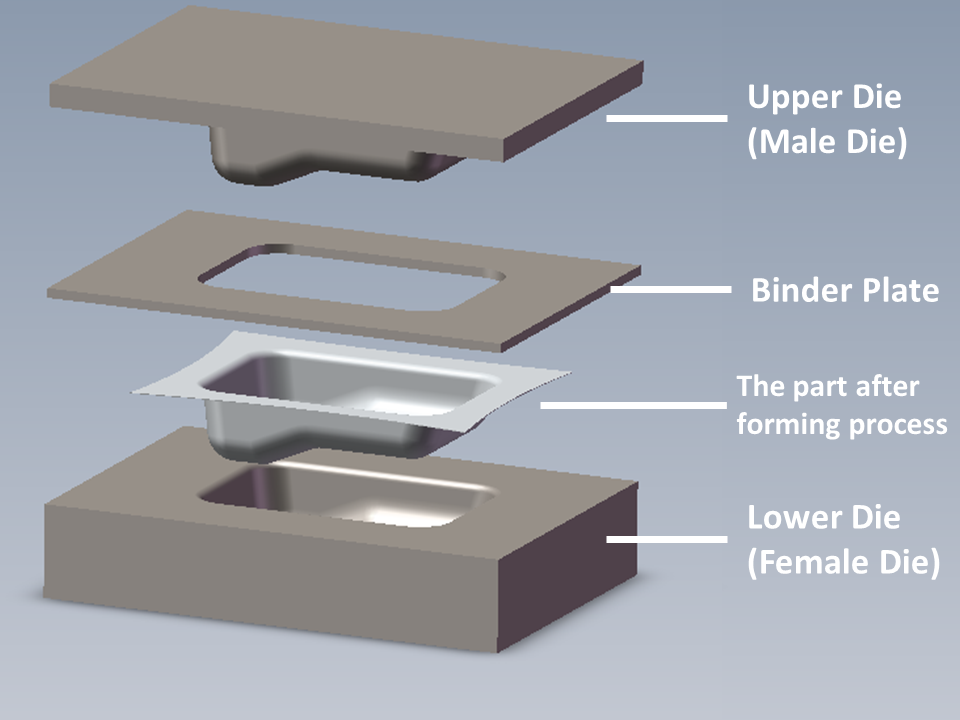

Deep Draw Metal Stamping - Charles richter specializes in everything from spheres and cylinders, cans and cups, to housings and housewares. Web stronger and smarter component solutions for your business. Anatomy of deep drawn stamping. Planning the part design every deep draw metal stamping process starts with planning the part design. Examples of typical deep drawn components include cans, housings, and other containers. Web deep drawn stamping process the process. Web deep draw stamping is a type of sheet metal forming that allows manufacturers to draw flat sheet metal into a die and then create the desired components. Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: Not only is it important to ensure that the die. Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions. Web metal stamping is a common manufacturing method within the hardware industry, supplying components for various residential and commercial applications. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. Charles richter specializes in everything from. Planning the part design every deep draw metal stamping process starts with planning the part design. Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions. Examples of typical deep drawn components include cans, housings, and other containers. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities. Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: Prospect machine products produces millions of… custom solutions for deep drawn medical device stamping Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions. Deep drawn stamping uses a greater amount of the base material. Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: Web precision metal deep drawn stamping is used to make practically any part and product out of sheet metal. Planning the part design every deep draw metal stamping process starts with planning the part design. Web metal stamping is a common. Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: Not only is it important to ensure that the die. Web the three steps to deep draw metal stamping are as follows: This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series. Web deep draw stamping is a type of sheet metal forming that allows manufacturers to draw flat sheet metal into a die and then create the desired components. Examples of typical deep drawn components include cans, housings, and other containers. Web metal stamping is a common manufacturing method within the hardware industry, supplying components for various residential and commercial applications.. Web deep draw stamping is a type of sheet metal forming that allows manufacturers to draw flat sheet metal into a die and then create the desired components. Deep drawn stamping uses a greater amount of the base material than other metal forming. Web stronger and smarter component solutions for your business. Anatomy of deep drawn stamping. This is accomplished. Web deep drawn stamping process the process. Not only is it important to ensure that the die. Deep drawn stamping is even used to make locks, appliances, and lighting components. Prospect machine products produces millions of… custom solutions for deep drawn medical device stamping Web stronger and smarter component solutions for your business. Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions. Because deep draw stamping can create specialized parts, it requires manufacturers who have experience in this precise process. Deep drawn stamping is even used to make locks, appliances, and lighting components. Web precision metal deep drawn stamping is used to make practically any part. Prospect machine products produces millions of… custom solutions for deep drawn medical device stamping Web metal stamping is a common manufacturing method within the hardware industry, supplying components for various residential and commercial applications. Deep drawn stamping is even used to make locks, appliances, and lighting components. Web the three steps to deep draw metal stamping are as follows: Because. Not only is it important to ensure that the die. This is accomplished by drawing a flat metal blank into a die cavity (or several cavities in a series of steps) with a punch until the metal has been shaped into the desired form. Web precision metal deep drawn stamping is used to make practically any part and product out of sheet metal. Because deep draw stamping can create specialized parts, it requires manufacturers who have experience in this precise process. Deep drawn stamping uses a greater amount of the base material than other metal forming. Prospect machine products produces millions of… custom solutions for deep drawn medical device stamping Web deep draw stamping is a type of sheet metal forming that allows manufacturers to draw flat sheet metal into a die and then create the desired components. Aerospace energy storage medical products military & defense oil & gas semiconductor Web deep drawn stamping process the process. Web stronger and smarter component solutions for your business. Anatomy of deep drawn stamping. Charles richter specializes in everything from spheres and cylinders, cans and cups, to housings and housewares. Web the three steps to deep draw metal stamping are as follows: Web when considering deep drawn stamping for your manufacturing needs, it is important to be aware of the following: Deep drawn stamping refers to the process of forming sheet metal under compressive and tensile conditions.

Metal Prototype Stamping Deep Drawn Prototypes Rapid Prototyping

Deep Drawn &Metal Stampings RAO Deep Draw & Metal Stamping Sheet

Deep Draw Metal Stamping Getting Started

Tooling Design for Your Deep Draw Metal Stamping Parts

Tools for Deep Draw Metal Stampings Important Facts by PMP

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

LESSONS LEARNED DEEP DRAW STAMPING Duggan Manufacturing

Deep Drawing New England Metalform, Inc., Precision Metal Stamped

Deep Drawn &Metal Stampings RAO Deep Draw & Metal Stamping Sheet

Deep Draw Metal Stampings & Formed Parts Hudson Technologies

Deep Drawn Stamping Is Even Used To Make Locks, Appliances, And Lighting Components.

Examples Of Typical Deep Drawn Components Include Cans, Housings, And Other Containers.

Planning The Part Design Every Deep Draw Metal Stamping Process Starts With Planning The Part Design.

Web Metal Stamping Is A Common Manufacturing Method Within The Hardware Industry, Supplying Components For Various Residential And Commercial Applications.

Related Post: