Coating Drawing

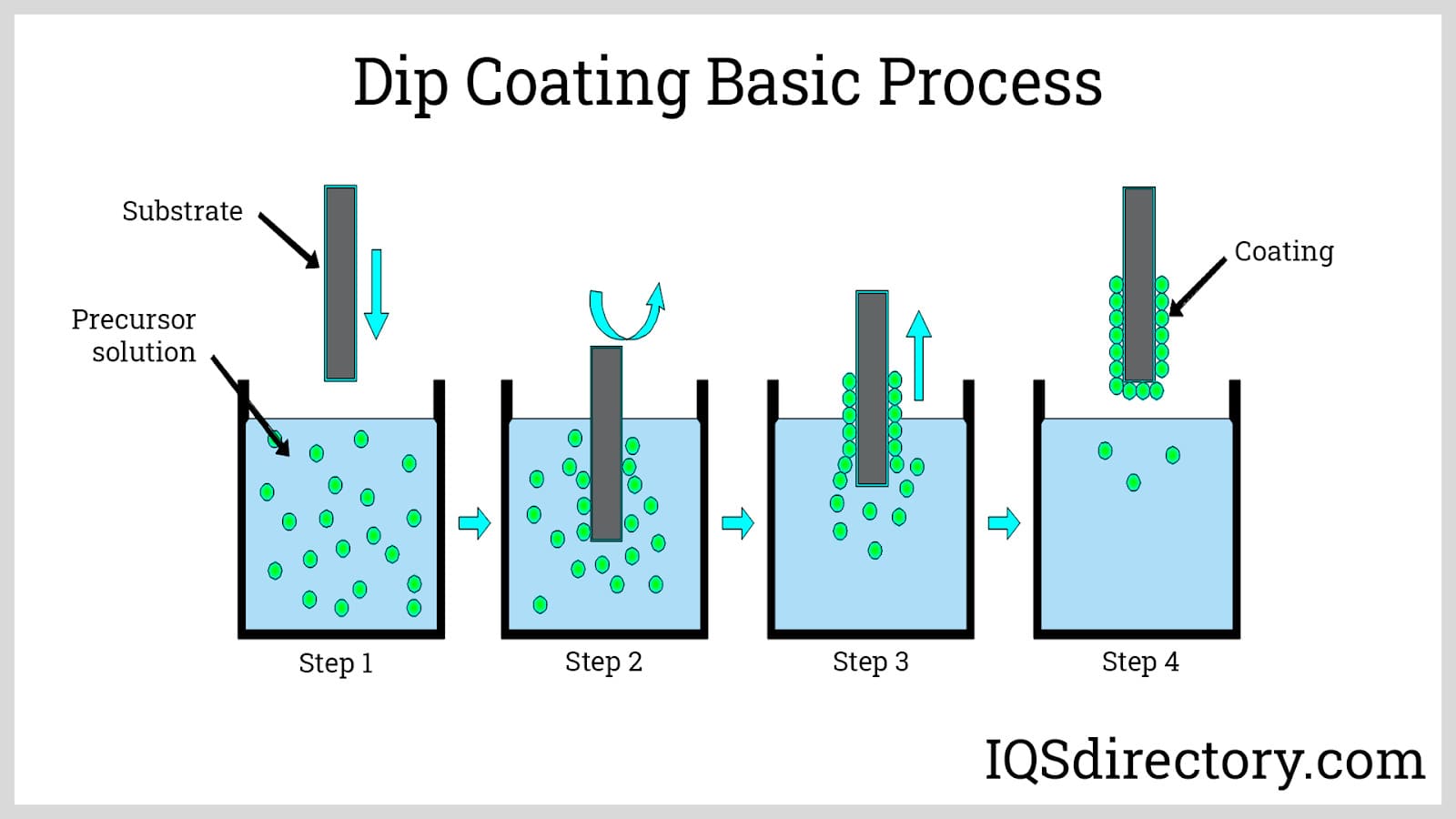

Coating Drawing - The hatching should be scaled and oriented within the drawing, but the. Web in wet drawing, liquid lubricants are mixtures of soap solutions with up to 3% oil. Web generally it is assumed that the conformal coating will cover the entire board, but your drawings should make this perfectly clear. Using a clean paintbrush, start applying the sealant to the painting in thin, even coats. Web a guide on the advantages, disadvantages, and ideal use scenarios of dip coating, spin coating, slot die coating, doctor blading, and bar coating. The wax is prepared by melting “encaustic medium” into a hot. Drawings and pictures are among the. Apply the sealant to the painting. Trim the papers to the correct size according to your drawing. Thin films can be created. Web it would be nice to designate surfaces in the model, or drawing to be hatched in the drawing. Make sure that you cover the entire surface of. Their cores are made of very finely ground pigment bound with hard wax. Soap emulsions with water and fatty oils may be used for copper, silver, gold and platinum. Trim the papers. Web pdf | modern coating methods have become an important part of industrial practice. The hatching should be scaled and oriented within the drawing, but the. Thin films can be created. Web now here’s what i learned from shawna on how to get started with encaustic painting: Web here is some information on pcb conformal coating standards, with an emphasis. Web does anyone know the proper method for noting an area to be masked from a coating on an enginering drawing? Trim the papers to the correct size according to your drawing. Apply the sealant to the painting. 8 principles and tips to improve engineering drawing skills. Web generally it is assumed that the conformal coating will cover the entire. Web now here’s what i learned from shawna on how to get started with encaustic painting: Using a clean paintbrush, start applying the sealant to the painting in thin, even coats. Web here is some information on pcb conformal coating standards, with an emphasis on how the ipc conformal coating standards can help you with your pcb design. Web part. Drawings and pictures are among the. I have a part that will be painted everywhere. Soap emulsions with water and fatty oils may be used for copper, silver, gold and platinum. Web now here’s what i learned from shawna on how to get started with encaustic painting: Thin films can be created. The hatching should be scaled and oriented within the drawing, but the. Web a guide on the advantages, disadvantages, and ideal use scenarios of dip coating, spin coating, slot die coating, doctor blading, and bar coating. Make sure that you cover the entire surface of. Web does anyone know the proper method for noting an area to be masked from. Web part 9 specifies surface treatment and coatings, and can be indicated one of two ways as shown in the figure below. Using a clean paintbrush, start applying the sealant to the painting in thin, even coats. Web a guide on the advantages, disadvantages, and ideal use scenarios of dip coating, spin coating, slot die coating, doctor blading, and bar. Web it would be nice to designate surfaces in the model, or drawing to be hatched in the drawing. For boards with areas that are not to be. Web a guide on the advantages, disadvantages, and ideal use scenarios of dip coating, spin coating, slot die coating, doctor blading, and bar coating. I have a part that will be painted. Make sure that you cover the entire surface of. Web now here’s what i learned from shawna on how to get started with encaustic painting: Web generally it is assumed that the conformal coating will cover the entire board, but your drawings should make this perfectly clear. For boards with areas that are not to be. The wax is prepared. Their cores are made of very finely ground pigment bound with hard wax. Web it would be nice to designate surfaces in the model, or drawing to be hatched in the drawing. The hatching should be scaled and oriented within the drawing, but the. Make sure that you cover the entire surface of. The wax is prepared by melting “encaustic. Oating thickness can often be ignored for machined parts. For boards with areas that are not to be. I have a part that will be painted everywhere. Web now here’s what i learned from shawna on how to get started with encaustic painting: 8 principles and tips to improve engineering drawing skills. Web it would be nice to designate surfaces in the model, or drawing to be hatched in the drawing. Web a guide on the advantages, disadvantages, and ideal use scenarios of dip coating, spin coating, slot die coating, doctor blading, and bar coating. Soap emulsions with water and fatty oils may be used for copper, silver, gold and platinum. Web pdf | modern coating methods have become an important part of industrial practice. Thin films can be created. Web colored pencils are stable and permanent. Web their advantages include high flexibility and suitability for deep drawing. Web in wet drawing, liquid lubricants are mixtures of soap solutions with up to 3% oil. Everyone has one or two in their homes! Web here is some information on pcb conformal coating standards, with an emphasis on how the ipc conformal coating standards can help you with your pcb design. Their cores are made of very finely ground pigment bound with hard wax.

Patent US7799420 Method for producing a nonostructured functional

coatings & paintings drawings YouTube

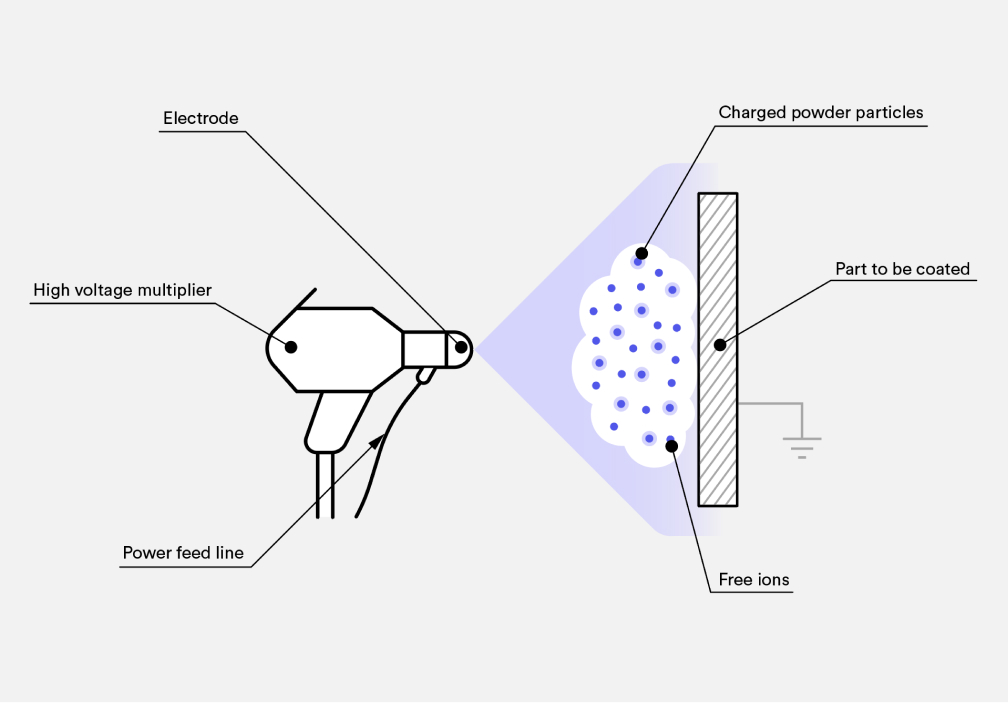

Powder Coating Electro Polish Dayton, Ohio Black Oxide, Aluminum

Powder coating services Surface finishing Hubs

Schematic drawing of the threestep spraycoating procedure. First, a

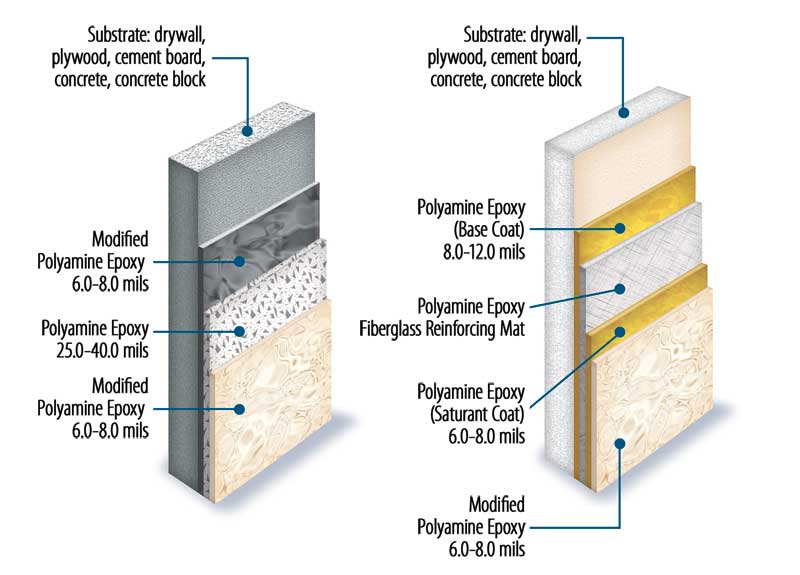

Schematic drawing of coating layers of precoated steel sheet

Industrial Coatings Types, Applications, Benefits, and Techniques

Applying coating systems for labs Page 2 of 2 Construction Canada

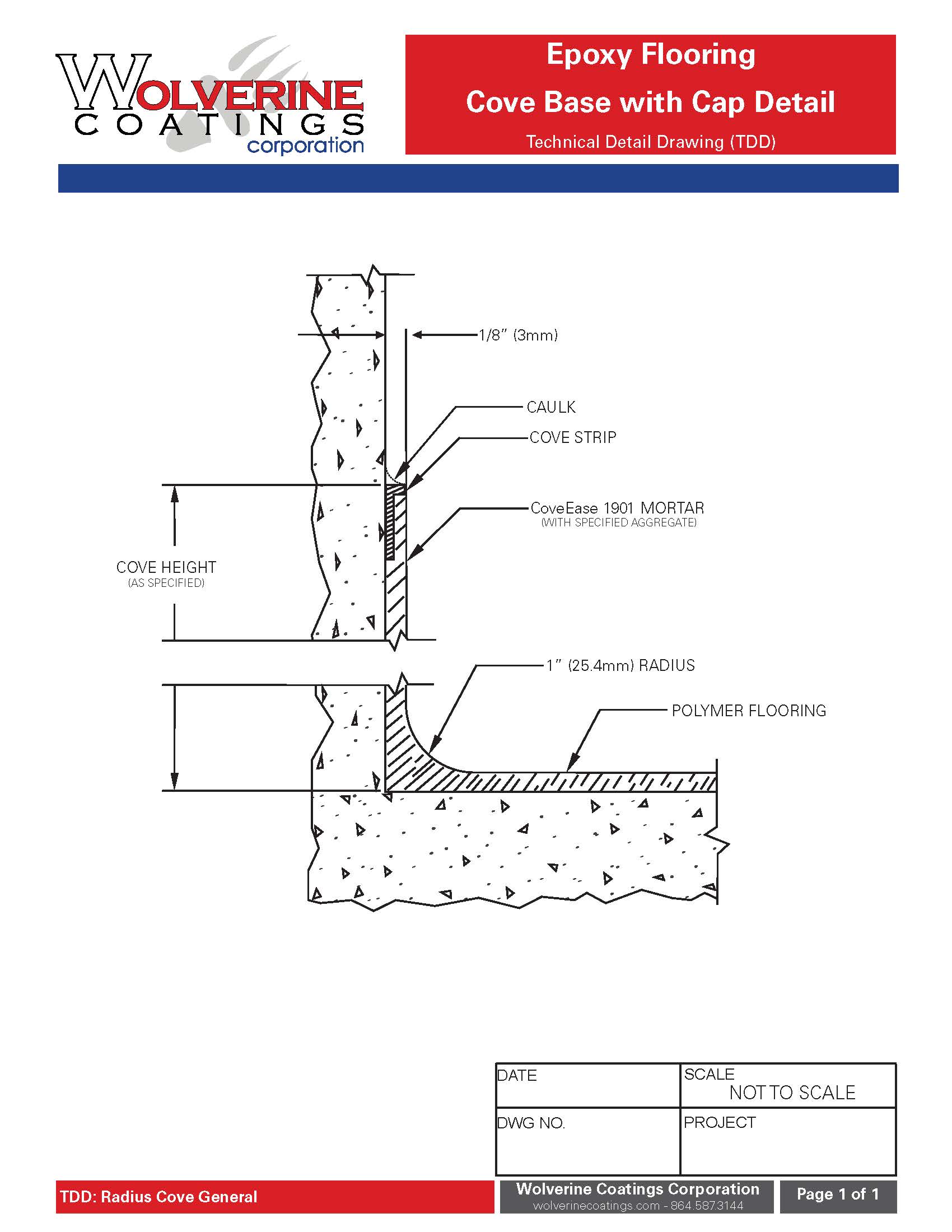

Technical Detail Drawings (TDD) Wolverine Coatings Corporation

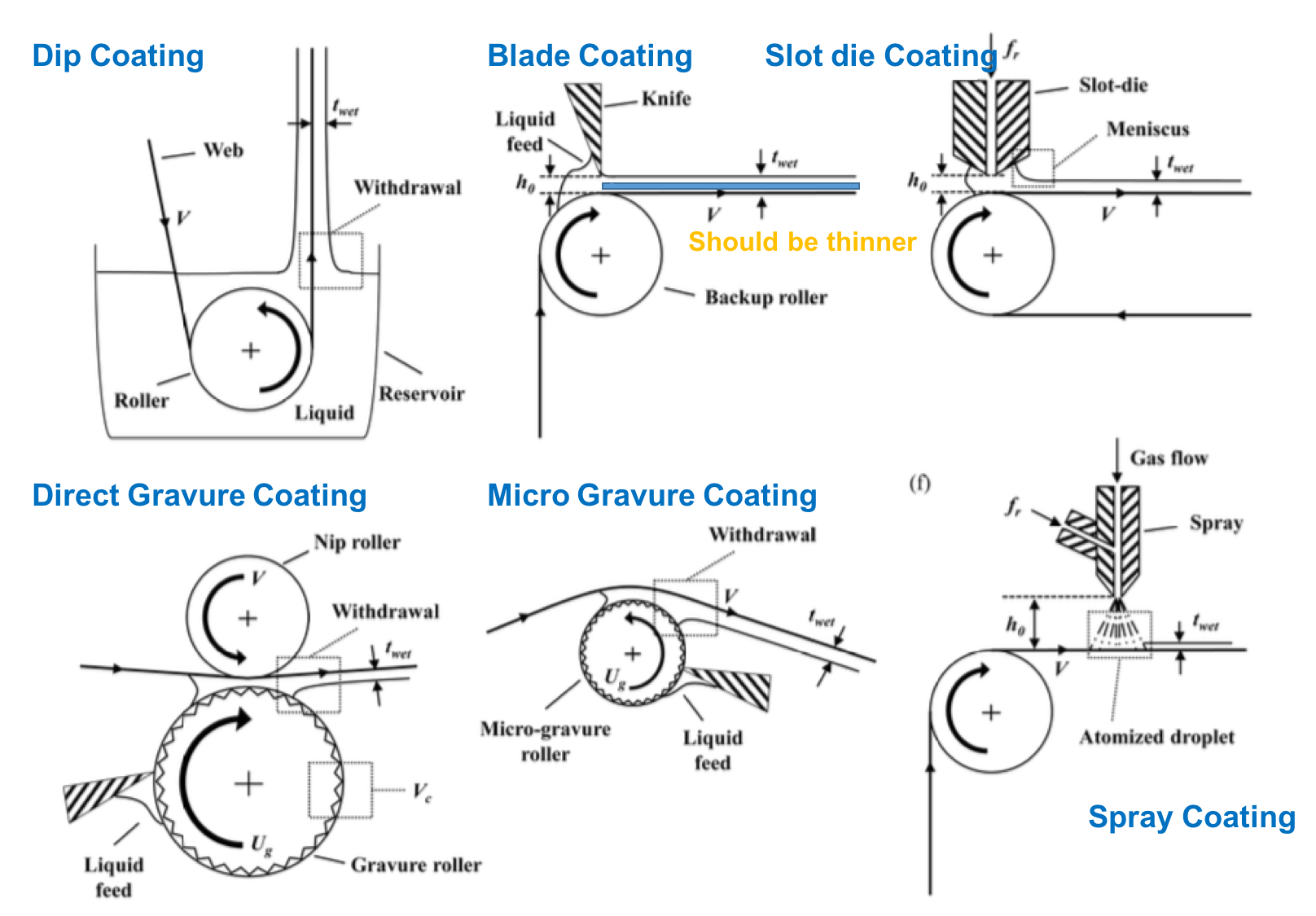

Major coating method and thickness control Paul Wu's Blog

Trim The Papers To The Correct Size According To Your Drawing.

Apply The Sealant To The Painting.

Web Generally It Is Assumed That The Conformal Coating Will Cover The Entire Board, But Your Drawings Should Make This Perfectly Clear.

The Wax Is Prepared By Melting “Encaustic Medium” Into A Hot.

Related Post: